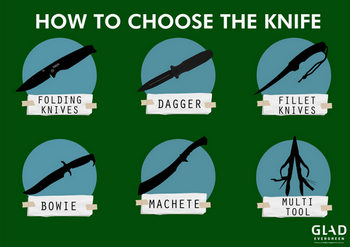

How to choose the knife:

First of all, you have to decide what you want the knife for: what is it for? Which features are necessary, or which of them are more important? Target the function you want for the knife and choose it based on the proportion of its function.

According to the structure of knives, they can be classified as fixed blade knives, folding knives, and utility knives such as Swiss knives and multitools. The advantage of fixed blade knives is hard and sturdy, and there are few places that can be broken; As for the folding knives, they are portable, but the locking varies in quality. The multitool is multi-purpose, and it is recommended for beginners to carry because they cannot only learn how to carry tools safely and correctly but also solve many problems encountered in the daily life.

Fixed blade knives can be divided into the full tang and partial tang. Full tang has the most complete and sturdy structure, so it will be used for most outdoor, tactical, and military knives. However, it is heavier than the partial tang. The partial tang is relatively a lighter option. Although the structure of it is not strong enough as that of the full tang, the incredible design and processing skills will make it better.

There are safety locking and non-safety locking knives. The folding knives had no safety locking design more than 2,000 years ago, and we had reliable safety locking folding knives until BUCK 110 was launched in 1964. The folding knives with safety locking are prohibited to carry in some countries, so remember to select the types of folding knives you can carry in your local area.

After determining the function and the type of structure of the knife you want, we have to consider the detailed places about knives. The following points are a brief introduction to the knives.

1. The thickness of the blade: When the thickness is thicker, it’s easier to split the wood. But the disadvantage is heavy, and it will be difficult to do meticulous cutting. Relatively, when the thickness is thinner, it will be lighter and easier to do the cutting, but the disadvantage is that not as strong as the thicker blade. In general, if the blade length is less than 6", the thickness ratio would be 1": 1mm. For example, a blade length is 3” with the thickness 3mm. Even some manufacturers increase the thickness due to design concepts and other factors, but in practice, the knifes will not break in normal usage if making according to this ratio unless the steel problem itself or heat treatment.

2.Blade Length: Blade length is the length from the guard or edge to the tip of the blade. In general, the knife will be easier to control when the length of the blade is shorter; and the longer, the more powerful. Based on past experience over the years and ergonomics, the different length will have different functions as following.

Below 2”: a portable tool which use for pencil sharpening. The cutting ability is not good unless it’s serrated. It is easy to carry and has no legal problems.

2~ 3”: The length of pocketknife is suitable for carrying and have a great cutting ability. In general, 90% cutting work can be executed in this length. The Swiss knife and the knives of multitool belong to this area.

3~4”: Large folding knife and small hunting knife: The length of this size of the knives are practical. It will be your great assistance when it comes with work in the field and in general work. The handling of the knives is great, with high accuracy and easy to cut. The 4” knife can deal with various sizes of prey, which is the smallest size among hunting knives.

4~ 5”: The standard length of hunting knife. It is easy to carry, and it’s long enough to handle all kinds of prey. It is the most popular length of hunting knife. It’s also the length of small self-defense combat knife, and it is often made in the form of boot knife. It’s the preferred length for the EDCSK (Everyday Carry Survival Knife) nowadays.

6~7”: Small combat knife. The longer the knife is, the worse handling gets, especially when it comes with cutting and stabbing. Usually if the length of knife is longer than 7”, the knife cannot be controlled very finely, therefore 7” is the upper limit of small combat knife.

7 1/2”:Survival Knife: The size is between the small and large combat knife (8~9”), which has great controllability for delicate tasks and the ability of hack and chop with field work. It is the general size of survival knife.

8~9”: Large combat knife: The attack method of this size knife is mainly hacking and chopping, partially is stabbing. It can also use as an alternative for hand axe. It is convenient to carry, therefore this size of combat knife is commonly used by the military.

9~12”: Machete (Bolo). The current definition of Bolo and Machete is that Bolo mainly used on woody plants, while Machete is used on herbs, vines, and woody plants with a diameter less than 5cm. The knife that can hack properly should be at least 9", and when it exceeds 12", unless the blade is thickened, it is easy to hurt yourself and damage the knife when cutting trees.

12~ 18”: Machete. Machete is the opposite of Bolo, because it mainly deals with grass and vines, therefore the blade is thin and long to work the best when it comes with opening the path. It will be difficult to control with one hand when the length of the knife exceeds 18”. Although there are Machetes made 24”, but most of the people still preferred 18”.

Hollow Grind: Grind a groove on both sides of the blade, it is easy to process and design machines to grind. The biggest advantage is that it will produce a very light blade, and the lighter the blade is, the cutting works better. The disadvantage is that the thinner the blade is, the weaker it is. It can cut those hard objects or tissues, but it is not suitable for chopping food when you cook. Because the longitudinal section of the blade is nonlinear, it cannot cut too deep. The grinding knives are not recommended for hacking and chopping, as the blade is fragile. The biggest advantage is to increase the cutting function of the blade, especially when the blade is not wide enough.

Chisel sharpening, blade grinding (Chisel Grind): only one side of the blade surface is grinded.

Advantage:

1.Easy to process: Grinding on one side requires only half of the time on process than other ways of grinding, and it does not need to be too precise, therefore it could save time, labor, and money.

2.Easy to grind: Unless there are serious damages, otherwise only one side grinding is needed, and the grinding technology does not have to be as superb as other grinding methods.

3.Material saving: In the early days of hammering knives, this grinding method does not need to cut off excess steel like other grinding methods, which can save the most consumption of steel.

Disadvantage:

1.Unable to cut accurately: When you use chisel grinding and other double-sided grinding knives to cut apples, you will find that double-sided grinding knives can accurately cut apples in half, while chisel grinding knives will inclined out according to the angle of grinding.

2.Unable to cut deeply: The chisel sharpening creates too many bevels on the point of knives, making it create more obstruction points and more difficult to pierce.

Flat Grind/V Grind: It’s a grinding method that combines sharpness and firmness. Flat grinding from the back of the blade to the edge gives it strong back and ridge. This grinding method is more difficult to grind compared with the two methods above, because a lot of steel need to be grind off during the grinding process. The blade is very thin and sharp, and it is suitable for all kinds of outdooring knives, therefore it is a great grinding method. It is also called V-grinding because it looks like a V-shape from the longitudinal section of the knife.

Sabre Grind: It’s like the flat grind. It is a design without grooves on both sides of the blade. The difference is that the flat grind is to grind from the back of the blade to the edge, while the Sabre grind is to start grinding from the middle of the blade. It also has excellent cutting and chopping function. The Sabre knives from early stage were made by this type of grinding, that’s why it’s called the Sabre grind.

Convex Grind: It also known as Moran Grind, because Bill Moran is the best knifemaker from the west who developed this. This grinding method is not like the four methods the ones mentioned above.

Other grinding methods are to form a bevel or groove on both sides of the knife, while convex grind is to form a double convex arc above the blade edge (because it looks like a clam, it is also called clam blade in Japan). This grinding method is as firm as flat grind and sharp as hollow grind. It is a very difficult way of grinding. The disadvantage is that if you don't have a Flat-Belt Grinder, it's hard to grind by yourself when the blade is dull.

Scandi Grind: It is the traditional way of grinding from Nordic, it does not have a second grinding surface (Secondary bevel). Like a chisel, there is only a primary grinding surface (Primary bevel). The advantages are that it is very sharp, able to cut easily, and it is easy to grind; the disadvantage is the blade is more fragile. Nowadays, Bushcraft has become a preferable grinding method for many people.

In the knife market, the material of using to make knives can be divided into three categories: carbon steel, stainless steel, and other materials. The choice of steel is based on what you expect the task the knife does and the environment. A steel suitable for cutting trees on a mountain is not necessarily suitable for using in the sea, while the cheaper material like 440A or 420 stainless steel may have a better performance than other expensive steels such as S-30V when it comes with activities in the sea. It is important to choose steel based on your needs.

Carbon steel is the earliest material used to make knives. Because carbon steel is easy to grind and has great tenacity. It is suitable for outdoor using. The disadvantage is that it is easy to rust, but the level of rust will only be limited to the surface if the carbon steel knives are made with excellent heat treatment. The oxide is iron tetroxide, and the oxide layer is relatively dense, which can prevent continued oxidation.

High carbon stainless steel is currently the mainstream in the knife industry. Starting from the earliest 440 series to 154CM/ATS-34, AUS series to the most popular S-xxV series, and the current S-xxV series is the steel that designed for knife making industrially. The advantage is that it is not easy to rust. Of course, there have been developed other steel types that do not rust at all (such as H1… etc.).

Besides, the steel series including titanium alloys, Talonite, Colbalt, ceramics, etc. These are the materials that used on the special purpose knives, some for anti-rust, anti-magnetic, and some for passing metal detectors or not leaving the smell when cutting food.

Due to factors such as materials or ways of construction, the prices vary widely. In general, you can find many high-quality knives in the price range within US$100 at the beginning, then you can move to a higher price range when you know what you are looking for.